The pad printing process is a quick and cost-effective method for adding quality images to substrates with curves, unusual shapes, or difficult surface textures. While the exact printing parameters will depend on the application, all pad printing processes involve the following basic steps:

A Specialized Print Technology

Used for a Variety of Industries

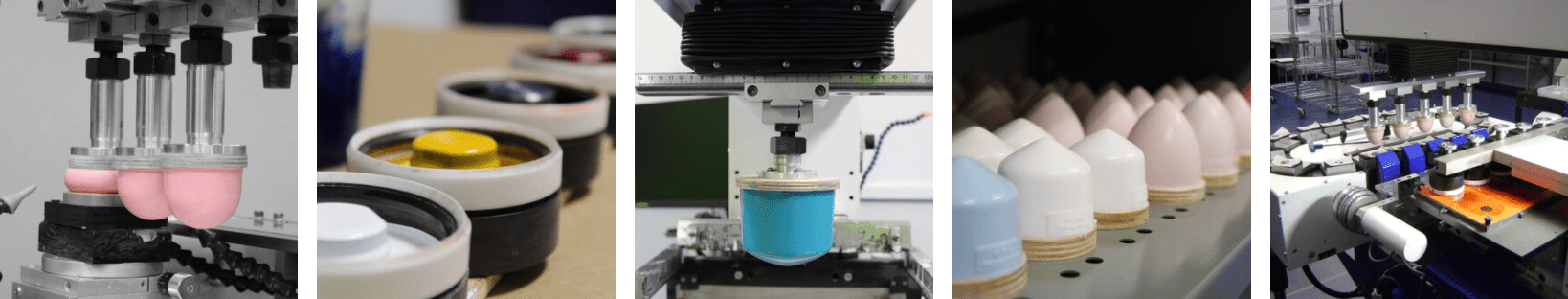

Pad printing is a unique printing process used for transferring 2-D images onto 3-D objects. Like the name, this technology utilizes a silicone ‘pad’ to essentially pick up an image (such as your logo) and transfer it onto a designated object (your product). This technology is typically used to print on difficult or oddly shaped surfaces like a golf ball, toy, syringe or remote. From single-color transfers to a detailed CMYK print process, or even from printing flat objects to oddly shaped ones, pad printing jobs can be complex.

Click here for more common pad printing examples.

Why Pad Printing?

Pad Printing Offers Distinct Advantages

Pad printing is an indirect offset printing process in which a soft silicone pad is used to transfer a two-dimensional image to the surface of a three-dimensional object. This unique printing method allows detailed images to be added to delicate, mechanically sensitive, or irregularly shaped products that would otherwise be difficult or impossible to print. With its versatility, reliability, and low cost, pad printing is a suitable printing option for everything from decorative consumer goods and electronics to precision medical devices and automotive parts.

What Is the Pad Printing Process?

- The image to be transferred is etched onto a flat print plate.

- An inverted cup filled with the printing ink glides across the print plate, flooding the etched sections of the plate with ink. When exposed to air, the ink becomes tacky.

- A smooth silicone pad presses itself into the ink-filled etched area of the plate. As the pad compresses, air is forced outward and ink is transferred from the etched plate to the pad.

- The pad then moves to the substrate and presses into it, depositing the image onto its surface.

3D Products

Ability to print on 3D objects of different shapes and sizes

Special Purpose Inks

Special purpose inks like security, thermochromic, photochromic, and confectionary

Quality Images

Higher quality images compared to other technologies

Sensitive Products

Can print delicate and mechanically sensitive products

Industrial Environment

Ability to print products that require withstanding industrial environments

Material Variety

Larger variety of materials compared to other technologies

Cost Effective

Offers a low cost print alternative for small space print jobs

Special Effects

Application of special effect inks like glow in the dark, neon, and shimmers

Pad Printing Supplies Overview

Several basic supplies and consumables are required to execute the pad printing process, each of which is described below.

What Is a Pad?

What Is a Pad Printing Machine?

What Is an Ink Cup?

What Is a Pad Printing Plate?

What Are Pad Printing Inks?

Additional Pad Printing Supplies

- Hardeners

- Solvents

- Retarders

- Primers

- Ink thinners

What Can Be Printed Using Pad Printing?

The unique ability of the silicone pad to conform to unusual shapes or textured surfaces makes pad printing a valuable printing technique in numerous industries and applications. Examples include:

- Medical: Accurately applying images on curved or hollow medical instruments such as syringes, catheters, tubing, inhalers, and insulin pins

- Pharmaceutical: Printing high-quality images on the surface of tablets, soft gels, hard gels, and capsules

- Cosmetics: Adding decorative images to cosmetic bottles, jars, caps, and lipstick holders

- Food and beverage: Printing on food packaging surfaces, drink bottle caps, corks, and more

- Automotive: Decorating automotive components with abrasion-resistant images

- Electronics: Adding eye-catching images and brand logos to intricately shaped electronic devices

- Sporting goods: Printing high-quality graphics on the surface of golf balls, mouth guards, and other difficult-to-print sporting goods

Pad Printing vs. Screen Printing

Screen Printing

Another popular printing method is screen printing, which uses ink, a mesh screen, and a squeegee to transfer a stenciled image onto a surface. Screen printing equipment is largely automated, allowing it to quickly and effectively print photorealistic images on large volumes of t-shirts and other items. However, this method is limited when it comes to capturing fine details or printing on hard, uneven surfaces.

Pad Printing

In comparison, pad printing can be used on virtually any surface type or material. Unlike screen printing, pad printing is particularly well-suited for applying images to irregularly shaped surfaces and conveying extremely fine details. This makes it the preferred choice for printing on small, uneven, or curved products, especially when working with intricate image designs.

Pad Printing at Teca-Print

Teca-Print is a leading manufacturer of precision-engineered pad printing machines and high-quality consumables such as print pads, clichés, and inks. From electronics and cosmetics to medical and automotive components, our printing solutions can be optimized to fit the needs of nearly any product. Our emphasis on continual process improvement has made us an expert in pad printing automation, research, and development, allowing us to provide customers with the most innovative pad printing technologies and features available.

We also offer extensive in-house sub-contract printing services, which include everything from product pre-inspection and preparation to multi-step printing, curing, and post-print inspection. To learn more about our pad printing products and comprehensive sub-contract services, please contact us today or visit our printing services page.